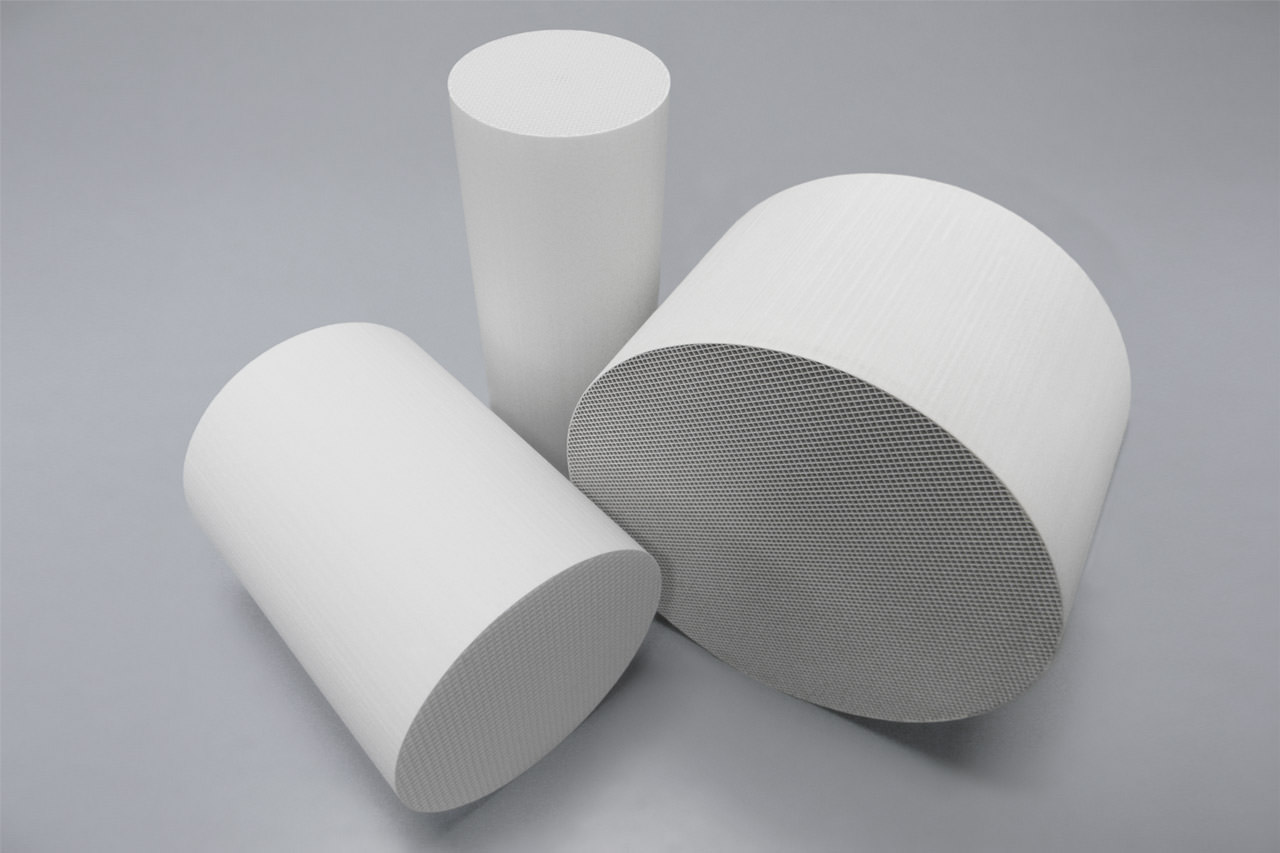

Industrial

Ceramics

Tylose cellulose ethers are used by the ceramic industry in various applications such as ceramic and powder metallurgical extrusion mixes as rheology modification and water retention additives.

Furthermore, the high binding power of Tylose plays an important role in spray drying and agglomeration granuling and the related powder pressing processes. Tylose is compatible with most other additives such as dispersants, plasticisers and surfactants. It is easily integrable into existing formulations, and it shows an excellent debinding behaviour.